Purpose MOS

Network Magnetic Strainer MOS is an appliance which functions primarily as a magnetic-reticular filter. The device is intended mainly for separation of solid impurities from water heating and cooling systems. Excellent operation results, particularly highly efficient separation of impurities of a very high comminution and partial reduction of sediment-forming processes secure the Network Magnetic Strainer MOS a top position among such devices as network strainers, magnetic filters, magnetic separators etc.

Network Magnetic Strainer MOS is an appliance which functions primarily as a magnetic-reticular filter. The device is intended mainly for separation of solid impurities from water heating and cooling systems. Excellent operation results, particularly highly efficient separation of impurities of a very high comminution and partial reduction of sediment-forming processes secure the Network Magnetic Strainer MOS a top position among such devices as network strainers, magnetic filters, magnetic separators etc.

Network Magnetic Strainer MOS is installed before the heat source in order to obtain highly effective and long-term faultless operation, mainly of water boilers, large heat exchangers or directly on supporting and returning lines of the above mentioned systems depending on individual operation requirements.

Technical Description

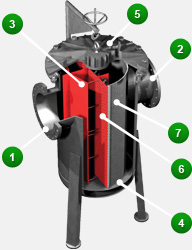

- cylindrical tank with inlet (1) and outlet (2) stub pipe

- steering partitions (3)

- sieve bottom (4)

- flat magnets situated on the partitions' walls (5)

- filtering screen permanently fixed to steering partitions (6)

- sieve filter (7)

Tank cover, partitions with screen and reticular filter have been made separately in order to enable cleaning of network magnetic strainer.

Operating principles

Inside the device, liquid (usually water or its solution) encounters a labyrinth of partitions, which force its direction and speed of flow. Properly oriented magnetic elements on partitions' walls realize the process of magnetic separation of magnetic solid phase and finely dispersive magnetic sludge from circulating liquid.

Device's outlet stub pipe is screened with sieve-reticular diaphragm with a large working surface, which enables separation of non-magnetic phase of granulation depending on applied bandwidth of the filter's mesh.

Device's outlet stub pipe is screened with sieve-reticular diaphragm with a large working surface, which enables separation of non-magnetic phase of granulation depending on applied bandwidth of the filter's mesh.

Thanks to its unique construction, i.e. combination of magnetic strainer OISm and network strainer, the Network Magnetic Strainer MOS enables an effective elimination of impurities out of circulatory liquid and greatly slows down the sediment-forming processes on the inner surfaces of the elements of heat transport and exchange.

Advantages

- 100% of the liquid supplied to the device is subjected to magnetic-mechanical filtration and additionally to the process of magnetic treatment

- Ability to separate micron particles of the suspension in magnetic traps while the nominal value of the flow is preserved for the entire series of Network Magnetic Strainers MOS

- slow increase of nominal (max 15 kPa) pressure drop is caused only by the extent of filter's mesh contamination (in heating and cooling installations non-magnetic solid phase practically constitutes no more than 5% of the total contamination mass)

- applying magnetic treatment of circulatory water (induction B and speed of flow V) has a similar effect as in the case of Magnetic Strainer OISm i.e. mainly anti-sedimentary action against boiler scale forming out of water and inhibiting corrosive processes

- the appliance doesn't require any form of energy supply, and its operation makes the reduction of corrosion processes absolutely environment friendly (minimizes or eliminates the need to apply corrosion inhibitors)

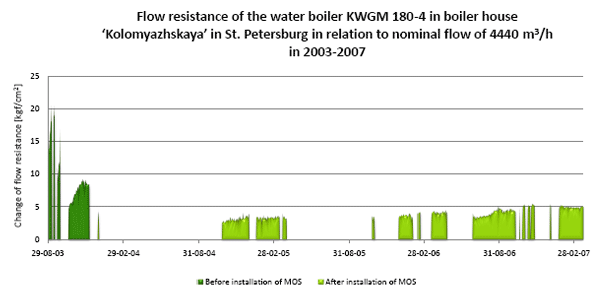

One of many examples of how heating facility operation has been effectively improved through the application of Network Magnetic Strainers MOS, is an operation of water boiler KWGM - 180 No. 4 in the boiler house of "Kolomyazhskaya" heating unit in St. Petersburg.

Since the mounting of Network Magnetic Strainer MOS 1200/600 on return wires, boiler maintenance service had not observed, till the end of 2007, any significant increase of the flow resistance in the pressure part of the analyzed boiler. It is noteworthy that the boiler has been working faultlessly since October 2004 in the range of nominal flow i.e. 4400m3/h.

Previously, due to continuous increase of flow resistance it was necessary to take a series of correcting actions each year, such as chemical cleaning or repair works of all boiler's pressure elements.

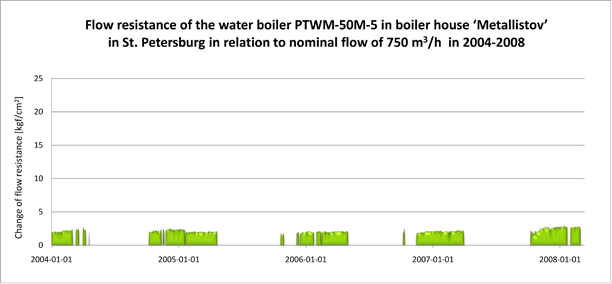

Another example of a satisfactory operation of a boiler, which has been protected with a MOS device from the moment of its installation, is water boiler type PTWM-50M No. 5 in the heating house in the Metallistov street in St. Petersburg.

On October 10, 2003, a 120 Gkal power boiler of nominal flow of 750m3/h was put into operation. Return wire in front of the boiler was equipped with Network Magnetic Strainer MOS 800/400. The work of the boiler in its nominal range hasn't so far been disrupted by an increase of the flow resistance, that would require undertaking correcting actions other than periodical cleaning of magnetic filter type MOS.

Since the mounting of Network Magnetic Strainer MOS 1200/600 on return wires, boiler maintenance service had not observed, till the end of 2007, any significant increase of the flow resistance in the pressure part of the analyzed boiler. It is noteworthy that the boiler has been working faultlessly since October 2004 in the range of nominal flow i.e. 4400m3/h.

Previously, due to continuous increase of flow resistance it was necessary to take a series of correcting actions each year, such as chemical cleaning or repair works of all boiler's pressure elements.

Contact

Contact

OŚRODEK BADAWCZO-SZKOLENIOWY

SPAW-TEST® Spółka z o.o.

ul. Śnieżna 1, 80-554 GDAŃSK

tel/fax (058) 343 77 45, 343 77 43

e-mail: spawtest@spawtest.pl

e-mail: biuro@spawtest.pl

Other products

Other products

Thermoinsulations

We also offer thermal insulations for Magnetic Strainer OISm.

read moreAcetylene fuses

BWS-D-4-0, 15 fuses protect acetylene generators and installations.

read more Other services

Other services

NDT of welded joints

Our Diagnostic Laboratory conducts non-destructive tests of welded joints.

read morePressure vessels and steel constructions

We make different types of vessels and steel constructions according to the client’s documentation.

read more

See also

See also